Return to Previous Page

An Overview of Thermowell Dimensions

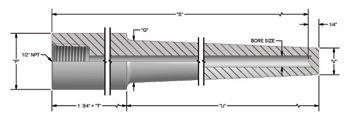

Threaded type: |

|

"U" is the insertion depth of the thermowell. This is how much of the thermowell will be inserted into the process fluid.The method of attachment (thread-o-let, pipe fitting…) will affect the insertion depth and needs to be considered when specifying this measurement.

"T" is the lag length of the thermowell. The purpose of lag is to provide extra length to clear any insulation, refractory… that may be between the process connection and the temperature sensor connection

point.

"P" is the process connection pipe size of the thermowell. The standard length of the threads for all pipe thread sizes is 1”.

"Q" is the root diameter of the thermowell and is based on the “P” dimension.

"V" is the tip diameter of the thermowell and is based on thermowell design.V = Q for straight-shank wells.

"S" is the bored depth of the thermowell.This dimension accounts for the length of the wrench flats, lag length, thread make-up, and insertion depth, less ¼”. This length is the same “S” length specification for spring loaded assemblies, designed for use with thermowells. The overall length of the thermowell is S + ¼”, since the thermowell is bored within ¼” of the tip.

The hex wrench flats are machined to ¾” in length.

For example, if we want our thermowell to be immersed 4” into the process liquid, and have 2” of insulation on our pipe:

U = 4”, T= 2”, the wrench flats = ¾”, and the threads = 1”.So the overall length of the thermowell is 7-3/4” and the “S” length is 7-1/2”.

Flanged type: |

|

A standard, flanged thermowell will measure 2-1/4” from the raised face on the process side of the flange to the end of the sensor side of the thermowell stem.For 1500 and 2500 class flanges, this distance will vary, due to flange thickness.

"U" is the insertion depth of the thermowell.This is how much of the thermowell will be inserted into the process, and is referenced from the raised face on the process-side of the flange.

"T" is the lag length of the thermowell.The purpose of lag is to provide extra length to clear any insulation, refractory… that may be between the process connection and the temperature sensor connection point.

"Q" is the root diameter of the thermowell and is based on the thermowell design.

"V" is the tip diameter of the thermowell and is based on thermowell design.V = Q for straight-shank wells.

"S" is the bored depth of the thermowell.This dimension accounts for the lag length, and insertion depth, plus 2”.This length is the same “S” length specification for spring loaded assemblies, designed for use with thermowells.The overall length of the thermowell is S + ¼”, since the thermowell is bored within ¼” of the tip.

For example, if we want our thermowell to be immersed 4” into the process liquid, and have 2” of insulation over our flange:

U = 4”, T= 2”, plus the standard 2-1/4”.So the overall length of the thermowell is 8-1/4” and the “S” length is 8”.

Weld-in type: |

|

A standard, weld thermowell will measure 1-3/4” from the transition point between the insertion stem and the weld portion of the well to the end of the sensor side of the thermowell stem.

"U" is the insertion depth of the thermowell.This is how much of the thermowell will be inserted into the process.

"T" is the lag length of the thermowell.The purpose of lag is to provide extra length to clear any insulation, refractory… that may be between the process connection and the temperature sensor connection point.

"P" is the process connection diameter of the thermowell.This can also be referred to as the OD or the welding diameter.

"Q" is the root diameter of the thermowell and is based on thermowell design.

"V" is the tip diameter of the thermowell and is based on thermowell design.V = Q for straight-shank wells.

"S" is the bored depth of the thermowell.>This dimension accounts for the lag length, and insertion depth, plus 1-3/4”.This length is the same “S” length specification for spring loaded assemblies, designed for use with thermowells. The overall length of the thermowell is S + ¼”, since the thermowell is bored within ¼” of the tip.

For example, if we want our thermowell to be immersed 4” into the process liquid, and have 2” of insulation on our pipe:

U = 4”, T= 2”, plus the standard 1-3/4”.>So the overall length of the thermowell is 7-3/4” and the “S” length is 7-1/2”.

Van Stone type: |

|

A Van Stone thermowell is a two-piece construction, where the flange slides over the temperature sensor end of the thermowell, applying pressure to a machined hub on the thermowell stem. This hub creates the gasket surface for

sealing the process.>The standard, Van Stone thermowell will measure 2-1/4” from the sealing face and the end of the

sensor side of the thermowell stem.>

"U" is the insertion depth of the thermowell.>This is how much of the thermowell will be inserted into the process, and is measured from the sealing face to the tip of the well.

"T" is the lag length of the thermowell. The purpose of lag is to provide extra length to clear any insulation, refractory… that may be between the process connection and the temperature sensor connection point. This length will be added to the standard 2-1/4”.

"P" is the process connection diameter of the thermowell. This can also be referred to as the OD of the temperature sensor side of the well or ID of the flange.

"Q" is the root diameter of the thermowell and is based on thermowell design.

"V" is the tip diameter of the thermowell and is based on thermowell design.V = Q for straight-shank wells.

"S" is the bored depth of the thermowell.This dimension accounts for the lag length, and insertion depth, plus 2-1/4”.This length is the same “S” length specification for spring loaded assemblies, designed for use with thermowells.The overall length of the thermowell is S + ¼”, since the thermowell is bored within ¼” of the tip.

For example, if we want our thermowell to be immersed 4” into the process liquid, and have 2” of insulation on our pipe:

U = 4”, T= 2”, plus the standard 2-1/4”.So the overall length of the thermowell is 8-1/4” and the “S” length is 8”.

Sanitary Connected type: |

|

A Sanitary connection type thermowell uses a sanitary cap as a mating component.A variety of commonly used caps are available to configure a thermowell. The standard length from the sealing face of the cap and the face of the temperature sensor end of the well is 1-3/4”.

"U" is the insertion depth of the thermowell.This is how much of the thermowell will be inserted into the process, and is measured from the cap face to the tip of the well.

"T" is the lag length of the thermowell. The purpose of lag is to provide extra length to clear any insulation, refractory… that may be between the process connection and the temperature sensor connection point.This length will be added to the standard 1-3/4”.

"P" dimension is not referenced on these wells as the standard connection is a ½” NPT bushing with a 1” nominal diameter.

"Q" dimension is not referenced on these wells as the standard well has a ½” nominal diameter.

"V" is the tip diameter of the thermowell and is based on thermowell design.V = Q for straight-shank wells, V= 5/16” for reduced tip wells.

"S" is the bored depth of the thermowell. This dimension accounts for the lag length, and insertion depth, plus 1-3/4”.This length is the same “S” length specification for spring loaded assemblies, designed for use with thermowells.The overall length of the thermowell is S + ¼”, since the thermowell is bored within ¼” of the tip.

For example, if we want our thermowell to be immersed 4” into the process liquid, and have 2” of insulation on our pipe:

U = 4”, T= 2”, plus the standard 1-3/4”.So the overall length of the thermowell is 7-3/4” and the “S” length is 7-1/2”.

Please reference the “THERMOWELL” section of the catalog for illustrative drawings.